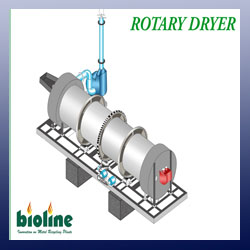

We Bioline Technologies are Manufacturers, Suppliers, Provider, Fabricators, Exporters Industrial Rotary Dryer. An Industrial Rotary Dryer is a large, heavy-duty drying machine used in various industrial processes to remove moisture or other volatile substances from a wide range of materials and products. These dryers are essential in industries like agriculture, mining, chemicals, food processing, and manufacturing. Here's detailed information about Industrial Rotary Dryers:The heart of an industrial rotary dryer is a cylindrical drum or shell, usually made of stainless steel or carbon steel, which rotates on its axis. The material to be dried is fed into the drum.Wet or moist material is introduced into the dryer through a feed system, such as a conveyor, screw feeder, or airlock valve. The material enters the drum at one end.

As the drum rotates, the material inside is exposed to direct or indirect heat sources, depending on the type of rotary dryer. The heat causes the moisture in the material to evaporate and escape.The heat required for drying can be provided by various means, including:Direct Heat: In direct rotary dryers, hot air or combustion gases are directly in contact with the material being dried.Indirect Heat: In indirect rotary dryers, a heat exchanger is used to transfer heat to the drum indirectly. This is often used when the material is sensitive to direct contact with hot gases.Inside the drum, lifting flights or paddles are strategically placed. These flights lift and tumble the material as the drum rotates, ensuring uniform drying and preventing material from sticking to the drum walls.Moisture-laden air or gases are vented out of the drum through an exhaust system. The exhaust typically passes through cyclones or bag filters to capture dust and fines before being released into the atmosphere.Once the material has reached the desired moisture content, it is discharged from the dryer through a discharge chute or conveyor system. Agriculture: For drying crops, grains, and animal feed.Mining: To dry minerals, ores, and concentrates.Chemicals: For drying various chemicals and chemical intermediates.Food Processing: For drying food products like fruits, vegetables, and dairy.Manufacturing: In processes such as plastic and rubber production.Environmental: To dry and condition biosolids and wastewater sludge.Wood Processing: For drying wood chips and sawdust in the production of wood-based products.Efficient moisture removal.High throughput and capacity.Versatile for various materials and industries.Uniform drying with good product quality.Flexibility in controlling moisture content.Energy-efficient options available.In summary, Industrial Rotary Dryers are crucial machines for moisture removal in various industrial processes. They come in different configurations and designs to meet the specific requirements of different industries and materials, contributing to efficient production and product quality. We Bioline Technologies are deeply engaged in offering a wide array of Industrial Rotary Dryer to our valuable Clients located in Mumbai, in Navi Mumbai, in Thane and all over India.